Grasping the Embroidery Digitizing Refine: Your Ultimate Guide

Needlework digitizing is a meticulous craft that needs precision and know-how to translate elaborate styles right into electronic formats for equipment needlework. As craftsmens start this journey to grasp the embroidery digitizing process, a thorough understanding of the fundamentals sets the foundation for excellence. Beyond the fundamental understanding lies a world of innovative software application, specialized tools, and nuanced techniques waiting to be checked out. By diving into the subtleties of digitizing, one can open a world of creative possibilities and elevate their embroidery projects to brand-new heights.

Recognizing Needlework Digitizing Essentials

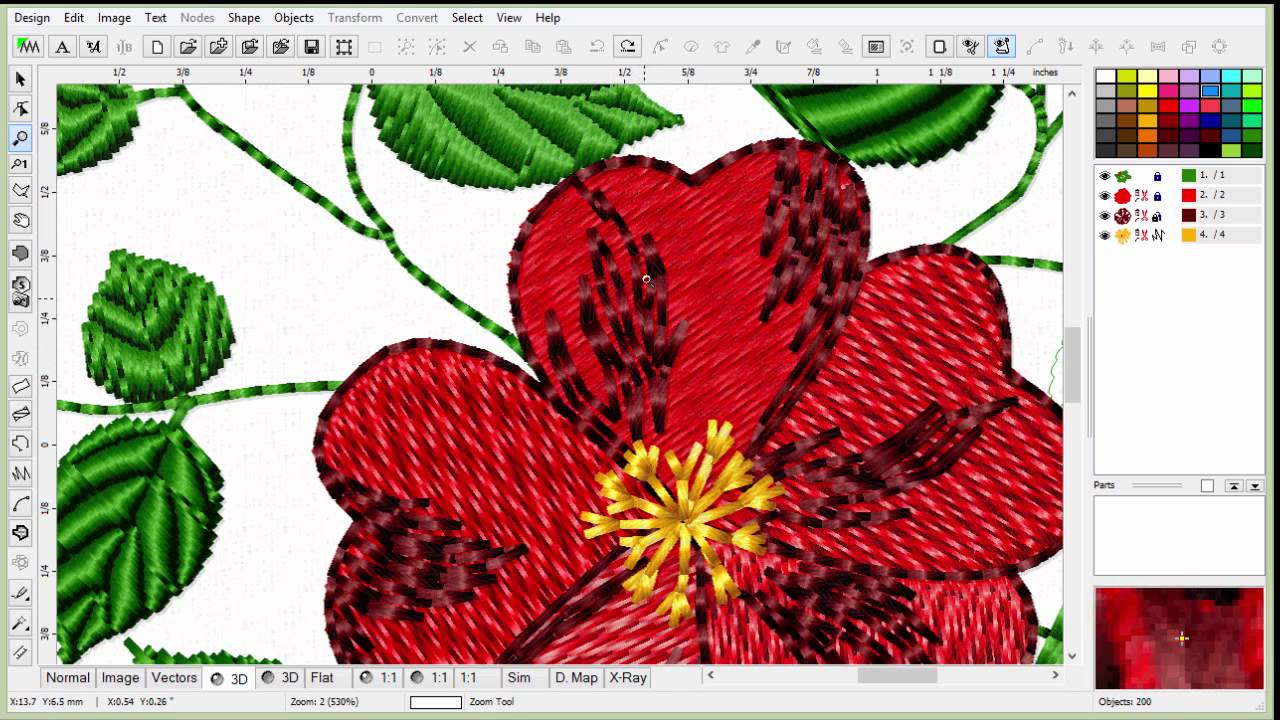

Embroidery digitizing essentials create the structure whereupon detailed layouts are converted right into machine-readable layouts for exact sewing. This preliminary action in the embroidery digitizing process is essential for guaranteeing that the final embroidered item is a loyal depiction of the original style. Understanding embroidery digitizing basics includes understanding crucial principles such as stitch kinds, stitch direction, thickness, padding, and pull compensation.

Stitch types play a vital function in identifying the visual and textural result of the stitched layout. By choosing the appropriate stitch type, whether it be satin, fill, or running stitch, digitizers can accomplish the preferred result and boost the total high quality of the embroidery. Furthermore, stitch direction influences the flow and dimension of the layout, while thickness establishes the spacing and insurance coverage of the stitches.

Moreover, rug sewing offers stability to the layout by safeguarding the fabric and preventing distortion throughout the needlework process. Pull settlement is an additional crucial factor to consider to combat the natural propensity of fabric to agreement when stitched. Understanding these embroidery digitizing basics is basic for producing professional-quality stitched products.

Selecting the Right Digitizing Software Program

Selecting the proper digitizing software is an important choice that considerably influences the efficiency and high quality of the needlework digitizing procedure. Digitizing for Embroidery. When selecting the appropriate digitizing software, it is vital to take into consideration factors such as the complexity of designs you plan to create, the user-friendliness of the software application, the level of client assistance used, and the compatibility with your needlework equipment

There are numerous digitizing software program alternatives readily available in the market, ranging from standard programs for beginners to advanced software program for specialist digitizers. Some preferred selections consist of Wilcom EmbroideryStudio, Hatch Needlework Software Application, and PulseID. These software provide a variety of tools and features to help you develop complex designs easily.

Prior to deciding, it is a good idea to check out the different software alternatives via complimentary trials or demos to establish which one best matches your demands. Furthermore, reading reviews and looking for suggestions from experienced digitizers can give beneficial insights into the toughness and weaknesses of each software plan (Digitizing for Embroidery). By very carefully assessing your requirements and contrasting the functions of different digitizing software program, you can make an educated option that boosts your needlework digitizing process

Digitizing Devices and Methods

Optimizing Style Setup for Needlework

Mastering the ins and outs of layout setups is basic in attaining optimum lead to the embroidery digitizing process, structure upon the structure laid by understanding digitizing tools and methods. Web Site When enhancing layout setups for needlework, it is vital to consider elements such as stitch kind, density, underlay, pull compensation, and registration. Sew kind option influences the overall appearance and feeling of the layout, with alternatives like satin, fill, and running stitches using various structures and effects. Density describes the spacing and density of stitches, impacting the design's coverage and sturdiness. Appropriate underlay sewing gives security and stops textile distortion, specifically for intricate designs or on elastic materials. Pull settlement readjusts for material stretch during stitching, making certain precise style replication. Enrollment setups line up different components of the design accurately, keeping total design honesty. By fine-tuning these style settings, embroiderers can enhance the top quality and precision of their stitched developments.

Troubleshooting Common Digitizing Issues

When running into common digitizing problems throughout the embroidery process, it is vital to comprehend the origin and execute reliable solutions immediately. One usual problem is stitch density problems, where stitches might be too dense, triggering the textile to pucker, or as well thin, leading to spaces in the layout. Readjusting the stitch density setups in the digitizing software program can help fix this concern.

Another constant difficulty is string breaks during the needlework procedure. This can take place as a result of various factors such as inaccurate stress setups, dull needles, or using low-quality string. Making sure proper upkeep of the needlework maker, consisting of regular needle changes and stress changes, can decrease the event of thread breaks.

Moreover, style registration errors can their website cause misaligned elements within the needlework design. Checking the layout placement in the digitizing software application and making essential modifications before sewing can assist in avoiding this concern. By resolving these usual digitizing concerns without delay and successfully, you can make certain a smoother needlework process and top notch completed products.

Conclusion

To conclude, understanding the needlework digitizing process requires a strong understanding of the essentials, the ideal choice of software, and expertise of devices and methods. Optimizing layout setups and fixing common digitizing concerns are vital steps in ensuring high-quality needlework results. By following these actions vigilantly, one can attain accuracy and efficiency in the digitizing procedure.